The most important economic news of 2022 was neither the war in Ukraine, with the energy price hikes that came with it, nor high inflation. The key event of 2022 was the intensification of the battle for control of the global semiconductor industry. This dispute experienced its most critical moment on October 7—although this was not the only significant event of the year—when the U.S. Department of Commerce announced new regulations to restrict China’s access to the most advanced processors and supercomputers, as well as the equipment and software needed for the manufacture of the latest generation of semiconductors.

These regulations, a really radical shift in U.S. trade policy, above all show the strategic importance of semiconductors. But they also reveal a now undeniable rupture between the two great world economic powers. Moreover, they show how the future of the world economy is being shaped.

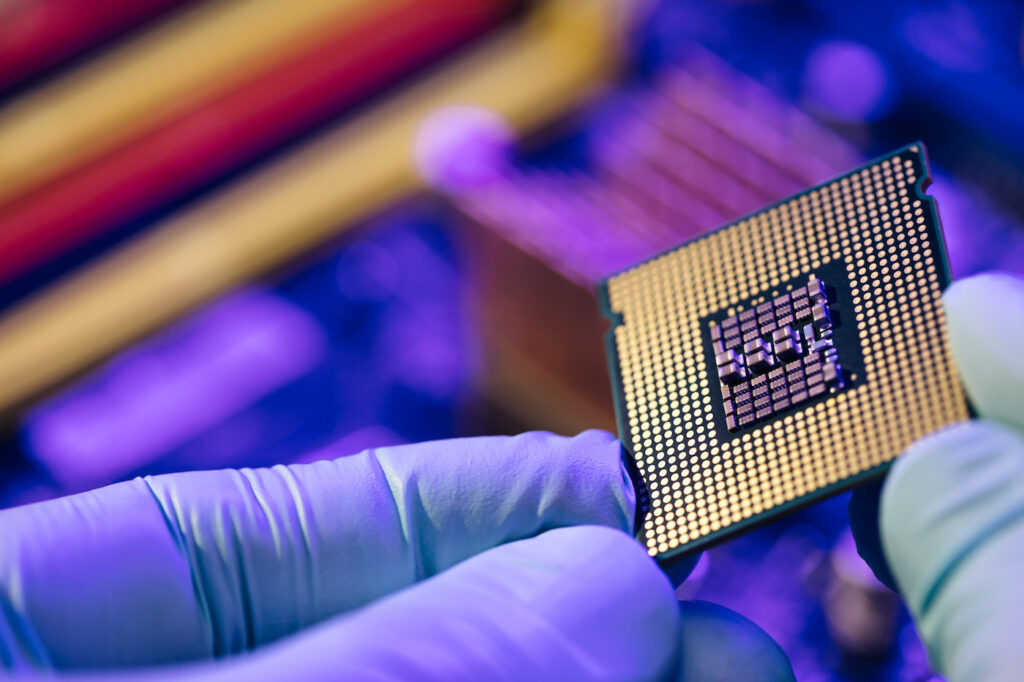

Let us start by identifying the issue. By semiconductor industry we mean the entire chain of design, manufacture, and installation of integrated circuits, called chips or microchips. These microchips are the basis for countless products such as the processors in computers and cell phones, the microcontrollers in cars, the television remote control, and many digital storage devices. It is almost impossible to think of the economy in 2023 without microchips. This article is written on a computer brimming with microchips, posted on the internet thanks to microchips, and read on a device (another computer, a tablet, a cell phone) crammed with, you guessed it, microchips. Even if you are reading this on paper, the printer you used is powered by them.

Semiconductors reveal a now undeniable rupture between the two great world economic powers. Moreover, they show how the future of the world economy is being shaped.

Start your day with Public Discourse

Sign up and get our daily essays sent straight to your inbox.But it is not just consumer goods that live on microchips: much of contemporary research, from biology to physics, depends crucially on the semiconductor industry. In my academic work, I am engaged in field called computational economics, which uses fairly advanced integrated circuits to measure the economic impacts of climate change.

In fact, doing without oil would be much simpler than doing without microchips. One can drive an electric car recharged with solar panels or nuclear energy, fly in airplanes that use biofuels and replace many of the products of the petrochemical industry with biotechnological alternatives. The problem with electric cars (or hydrogen cars, if one is concerned about the mineral limitations of batteries), biofuels or organic plastics is their cost, directly or indirectly (creating the necessary infrastructure, for example, for green hydrogen). But if it is feasible to reduce the oil consumption of a modern society by 95 percent, it is simply too expensive, and that is why it is so difficult to move toward the needed decarbonization of our economies. However, getting rid of microchips is not possible without giving up what we consider “modern life” (in fact, even today’s production of oil and its products depends on chips and microchips from top to bottom). To go back to vacuum tubes is to go back to the 1950s.

But it is no longer just that our economies depend on microchips: state military power is a direct function of them. Since the Vietnam War, the United States has committed to using microchips to multiply its military force. The success, a thousand times repeated, of the HIMARs in Ukraine is an unequivocal consequence of electronics: from the design of missiles to their in-flight control, or the gathering of intelligence to select targets. In comparison, Russia’s poor military performance has much to do with its technological backwardness. Were it not for its nuclear weapons, Russia would be a third-tier power today and would have lost the war in Ukraine months ago, probably after the intervention of NATO area forces.

The Rise of Semiconductors

The semiconductor industry was one of the earliest and most radical examples of globalization since the pioneering Fairchild Semiconductor opened its Hong Kong plant in 1963. Look at your cell phone. The chances are the basic technology has been developed in the United States, the architecture of the processors that run it is designed in the United Kingdom, the photolithography machines that make it possible to manufacture these processors were built in the Netherlands, the processor has been produced in South Korea, and the final assembly of the cell phone was carried out in China.

For many decades, this international division of labor benefited everyone. Without the low labor costs of East Asia, the first generations of chips would never have been cheap enough for mass adoption, which helped generate the enormous economies of scale that transformed the industry. At the same time, the semiconductor industry helped these East Asian economies begin their growth process. Without the specialization of different nations, we would never have been able to coordinate the myriad talents needed to build an advanced processor, perhaps the most sophisticated creation of mankind, which needed participation of more than seventy countries and more than one thousand different manufacturing processes.

The story of the extraordinary success began in the mid-1960s but culminated more or less in the spring of 2016. Two related forces converged in that spring. The first force followed from the organization of semiconductors’ exponential complexity. Gordon Moore, one of Intel’s co-founders, predicted in 1965 that the number of transistors on an integrated circuit would double every year. (He later reduced this prediction to every two years.) The exponential growth has been spectacular. One way to think about “Moore’s Law” is that microchips have advanced as much between February 2021 and today, February 2023, as they have from their invention in 1958 to February 2021. To put the point in a more obvious way: the cell phone in anyone’s pocket has vastly more capacity than the world-class supercomputer on which I ran part of my PhD thesis results in the fall of 2000.

Without the specialization of different nations, we would never have been able to coordinate the myriad talents needed to build an advanced processor, perhaps the most sophisticated creation of mankind.

Leaders in Microchip Production

Moore’s Law assumes that, at present, the latest generation of microchips have some 80 billion transistors, which are devilishly complex and incredibly expensive to develop and manufacture. The combination of complexity and cost has led to a dramatic reduction of companies in the sector: there is neither market nor capital for more. Making semiconductors of 3 nanometers or less, the industrial frontier in February 2023, is only within the reach of three companies worldwide: TSMC of Taiwan (the largest “foundry” in the world, which manufactures, for example, the processors of the Apple and AMD), Samsung of South Korea, and Intel of the United States.

But even this short list has a “catch.” Only TSMC knows how to produce 7 nanometer or smaller semiconductors on a massive scale. Samsung can produce them, but on a smaller scale than TSMC. For example, the rumors in the industry are that NVIDIA had problems with its graphics processing units (we will come back to them in a few paragraphs) because Samsung could not produce enough circuits, even in the less complex 8 nanometer process. The situation reached such a point that the president of South Korea released from prison Lee Jae-yong, the de facto head of Samsung, at the end of August 2022, to bring order to his company’s semiconductor manufacturing (which seems to have worked well).

Intel is suffering innumerable delays with its latest processors. There is a non-trivial possibility that Intel will fall off the list when the new generation of GAAFET transistors arrives (from all directions)—and which Samsung already employs in part as of June 2022. Intel has announced a 2-nanometer GAAFET for 2024, but will it be able to produce it in quantity and on time? The latest news is not very optimistic about it, and the delay in the arrival of Meteor Lake 14th generation, or even its possible cancellation, is very worrying for the prospects of American business.

In short and to skip all the technicalities: the most advanced, and in a sense the most vital product in the world economy, is only produced without problems or delays and on a sufficient scale in Taiwan. And the second best alternative, Samsung products, are produced in South Korea.

In theory, this would not pose a major problem. There is another basic element in the manufacture of advanced microchips: photolithography machines that “print” the circuit pattern on a silicon wafer. The most modern machines, which employ a technology called extreme ultraviolet lithography, have been developed to produce the circuit pattern on a silicon wafer (here is a simple explanation of how to generate this light). Only one company in the world, the Dutch ASML, produces them, largely because they have the best laser technology since they bought California-based Cymer. ASML has fantastic profits, and the existence of a competitor would mean lower prices for integrated circuits. But economists think that the welfare costs of such a worldwide monopoly are likely to be very low because of the existence of potential competitors constantly “chasing” the Dutch company. That ASML dominates this market does not take a second’s sleep away from us. That TSMC dominates the market for more advanced microchips does.

Geopolitical Tensions

The key difference between ASML and TSMC is, obviously, where each is located. ASML is located in the Netherlands, a century-old democracy in one of the most stable areas of the planet and with a centuries-long tradition of being reliable trading partners (Dutch pirates disappeared long ago and only exist today in movies). Except for Switzerland, it is difficult to think of a country with less geostrategic risks than the Netherlands. Taiwan is also a democracy, at the moment very vigorous, but it is at the center of the most fundamental geopolitical rift of our times: the Chinese Communist Party’s desire to “reunify” the island with mainland China (the risk of devastating earthquakes and tsunamis in Taiwan is not trivial either, but we shall leave that for another day). And, as was said before, the second best alternative, Samsung’s products, are manufactured on the Korean peninsula, which is no temple of tranquility either, considering its northern neighbor.

The second force putting the brakes on the international division of labor in the semiconductor industry was China’s policy shift with the coming to power of Xi Jinping in 2012. Xi, whose worldview is very different from that of his immediate predecessors, was concerned about two things. The first is that the international division of labor in the semiconductor industry did not leave China in a very favorable situation. According to a recent study, the United States produces 39 percent of the world’s value in this industry, South Korea 16 percent, Japan 14 percent, Taiwan 12 percent, Europe 11 percent (thanks mainly to the two companies already mentioned: ARM in the United Kingdom and ASML in the Netherlands) and China 6 percent. The potential gains for China, perhaps the world’s leading consumer of integrated circuits (exact figures are hard to come by, given that many of these circuits are used in products that are then re-exported and re-imported numerous times), for making progress in this industry are tremendous. Furthermore, China appears to be losing ground in this field, with its company SMICs. Given China’s existing human capital base, with excellent polytechnic universities, the country has the capacity to leap from 10 nanometer processes to 7 nanometer processes. And with thousands of PhDs from the best technology programs in the United States, it is logical and normal to aspire to play at the top of the league.

Without a leading semiconductor industry of its own, China will not have the military capability to challenge the United States for world military leadership and, for example, be able to “reconquer” Taiwan.

The second observation, much less benign than the first, is that, without a leading semiconductor industry of its own, China will not have the military capability to challenge the United States for world military leadership and, for example, be able to “reconquer” Taiwan. Returning to a previous point: the war in Ukraine makes it clear that thousands of outdated battle tanks are useless.

Similarly, without the best in-house processors it is difficult to exploit all the advantages promised by artificial intelligence, including its military applications such as programming advanced drones. As the great Alan Kay once said, people who are really serious about their software should make their own hardware. China has great deep learning researchers, but it is far behind in the graphics processing units, necessary to train deep learning models, a market clearly dominated by NVIDIA. Contrary to what is often claimed, at the end of the day China lags far behind the United States in artificial intelligence, and its brutal “surveillance state” requires a huge number of workers performing manual supervisory tasks.

To close this military technology gap, China began a policy of “civil-military fusion” at the end of the 1990s. But it was Xi who made this policy a top priority of his government, in terms of both funding and resources (legal and illegal) devoted to it. This has meant that we find ourselves in a situation very different from previous disputes in the semiconductor industry.

Japan in the 1980s, for example, employed very aggressive techniques to gain market share in this industry. Some techniques were legal and ethical (investing large amounts in research and development), others legal but unethical (“stealing” engineers from U.S. companies to employ them in positions that did not violate the letter of non-disclosure agreements with their former employers, but did violate the spirit). And some were neither legal nor ethical (illegitimate acquisition of intellectual property through bribes). But, despite some nationalistic rumblings in Japan, the United States did not consider such behaviors to cross any red lines. Japan was (and is) a staunch U.S. ally; American companies also often bent the rules, and the benefits of the trade relationship for both sides were so high that it was not worth disrupting that for such little matters. At best, we could have readjustments at the margin, such as disputes over Japan’s possible dumping. Beyond having to suffer through a bad movie, none of this had major consequences.

We now find ourselves with a dictatorship, China, eager to achieve global geopolitical leadership by using any means at its disposal. During the spring of 2016, the United States concluded that suddenly the semiconductor industry was its strategic priority. Energy is already much less relevant from Washington’s perspective: remember that the United States is already a net energy exporter and that it could live, if it wanted to, without importing a drop of oil from the rest of the world. The battle is now semiconductors.

How this semiconductor battle began in 2016 and how it has escalated to the new regulations on October 7, 2022, will be left for my second article, as a fascinating story that blends my major personal interests—economics, technology, and politics—and which merits a leisurely telling.

This article is adapted from a version originally published in February 2023 at El Confidencial, a leading Spanish digital newspaper. We are grateful to Professor Jesús Fernández-Villaverde for his permission to publish it in English here, and to Thomas Howes for his translation.